Creating a QMS at a DistanceCan an ISO 9001:2015 Quality Management System be developed in real-time with a consultant over the internet? Of course, it can. But like any other use of software and technology, we need to understand both the strengths and weakness of the tools were considering. Using readily available online meeting tools as part of an organization’s efforts to achieve ISO 9001:2015 compliance, companies can greatly reduce on-site consulting time and cost, through the use of web-based "virtual workspace" to increase productivity, as well as reduce both time and money spent on travel. Since most consulting assistance, and related outcomes, are organized around scheduled meetings, moving these activities online is just having the same meeting in an alternate format. It should be noted however, that online “virtual” or “remote” activities have inherent limitations, particularly being, they can only address those areas and activities that can be viewed online on a computer screen; other activities may likely require a more “hands-on” approach, which can usually only be satisfied by time spent on-site. To completely address all ISO 9001:2015 requirements, the ideal approach is combination of both virtual (off-site) and physical (on-site) consulting services. Using Remote TechnologyWith today’s technology, it is possible to collaborate with anyone, anywhere, using almost any web browser. In many cases, only an app or website login is required. This approach does not require any specialized software, so it can be scaled easily, at low or no cost, with limited technical expertise. As of this writing, some of the best online platforms for virtual meetings are shown below. I am sure there’s others, but these are the ones we use regularly, with the best results:

All the services noted above include user authentication and encryption, as well as some having multilayer security, in order to ensure that your information is always secure. We have however, found that organizations have widely varying levels of IT policy and controls implemented, so it is always best to consult and/or confirm with your IT department prior to stating which type of application is preferred and/or allowed. Remote Auditing TechniquesIt is also possible, using the same technology as above, to audit these systems either partially or completely. The overall approach used, and its adequacy, will depend on the organization, the scope of its management system, and the products and services that are being provided.

In certain cases, such as professional services, a remote audit may be enough to cover all areas. In other cases, such as in the manufacturing of products, remote auditing may be incorporated as a part of the organization’s overall audit program, but planning should still consider a physical assessment of activities as necessary to ensure not only the system has been implemented correctly, but also to ensure that appropriate physical controls have been implemented and are being maintained. In this later case, remote auditing techniques would be adequate for a portion of the audit, but not its entirety.

0 Comments

The COVID-19 Coronavirus As the COVID-19 pandemic sweeps the world, we’re faced with risks and opportunities that we never considered. Millions are forced to self-isolate; businesses are closing, employee layoffs are occurring, basic items such as toilet paper and hand sanitizer are in short supply. We are faced with challenges on a scale that are unparalleled since World War II, as we make our best attempt to “flatten the curve”. It is estimated that we are still several weeks away from being back to “normal”, if not months, or potentially even longer. It could even be that a new “normal” takes shape, one where this becomes a recurring concern, until such time that a vaccine is introduced and made available to the public. Risks and Opportunities As of this writing, we are facing health risks, including death, to our persons, our families and our neighbors; economic risks associated with the economy, the falling stock market, the security of our jobs, and the integrity of our supply chains. We also faced with the risks that both our livelihoods and lifestyles may be negatively affected by prolonged shutdowns, and the necessity of remaining in our homes. As we work our way through this pandemic, which we will, there will also be opportunities that follow, once of the first likely being a reduction in our dependence on imported manufactured goods and materials. We may potentially see a new era of domestic growth and expansion, with many industries revitalized as “Made in America” takes on a new meaning. We may also see new opportunities related to improvements in medicine, health care and social programs, as the coronavirus is now testing our current capabilities and capacity to its limits. Impacts to Business For most organizations, the consideration of a global pandemic was just not “on-the-radar”, and if it was, it was considered alongside other extraordinary events such as meteor strikes, volcanic eruptions, and alien arrivals. While such events would surely have a significant impact to the organization, their probability of occurrence was, until this point, considered low.

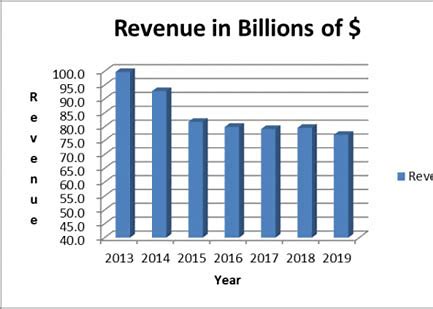

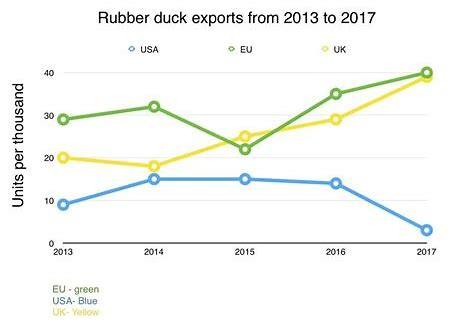

Now that we’ve reached this point, the impact of this pandemic has affected nearly every industrial sector. While I’m not sure that any business could develop and execute a contingency plan that is comprehensive enough to deal with all of the profound effects and impacts of this virus, hopefully it will emphasize the importance of considering potential risks and opportunities that may affect our businesses, prior to their occurrence. For those companies where the consideration of risks and opportunities was considered an academic exercise, required only for achieving and maintaining ISO 9001:2015 certification, the need to address such concerns through our planning activities should be clearer than ever. QMS Performance and TrendsThe trending of QMS performance is one of those subjects that comes up repeatedly. It is a frequent topic that arises in both the internal audits we perform, as well as during Certification Body (CB) audits we attend for ISO 9001:2015 certification, surveillance and/or re-certification. Before we jump too quickly into the topic of what QMS trends are and how they’re analyzed, it’s important to note that ISO 9001:2015 makes only one reference to the analysis of trends, as part of the requirement for Management Review Inputs (9.3.2). Per ISO 9001:2015 (9.3.2(c)), “information on the performance and effectiveness of the quality management system, including trends”, must be addressed for the following:

While this does not limit the analysis of trends to only Management Reviews, it is important to understand that the actual requirement specifically refers to the above seven items. The organization should feel free however, to analyze any other trends as necessary, and at any time of their choosing, to suit their specific business needs. What Is a Trend? In simplest terms, a trend is the general direction in which something is developing or changing. In this context, direction refers to “performance over time”, such as week-to-week, month-to-month, year-to-year. Rather than just looking at a result at a single point in time, we’re now able to see periods where QMS performance is trending upwards, downwards, or even trendless periods. Trend analysis may also be used to forecast performance into the future, if no action is taken. As for the period under consideration (weeks, months years, etc.), ISO 9001:2015 is not prescriptive on this matter, so the duration of time under review should be the one which is most appropriate for the data under consideration and your organization’s needs. While many auditors will decree this trending should cover multiple years, I don’t consider this to be an absolute, considering some data may be perishable, it’s collection (or retrieval) isn’t practical, or it may be affected by changes to either internal or external factors which may render prior data useless. How are Trends Analyzed When the subject of analyzing trends come up, the first thing that comes to mind is Statistical Process Control (SPC), followed by an immediate groan. While trend analysis does involve statistical tools, most trend analysis can be performed using simple techniques, and common software available to most users (think Microsoft Excel). Analyzing trends does not require a Quality Engineer, or a “green belt”, “yellow belt” “black belt”, or any other color belt of the six-sigma variety. Basic computer skills are usually adequate.

As for specific methods to be used, ISO 9001:2015 leaves a lot of room, as again, there’s no prescriptive requirement established here either. Trend lines, run charts, control charts, etc. are good when starting out, but keep in mind, by visualizing data in different ways, we’re able to uncover hidden or hard to understand tendencies that may otherwise go unnoticed. Performance Indicators and KPI’s In an earlier blog post, I gave a few examples of performance indicators, as well as described the relationship between performance indicators and Key Performance Indicators (KPI’s). The distinguishing feature between these two, is whether the performance indicator under consideration is relevant to the to the strategic outcomes determined by the organization. The take-away from all this being, all KPI’s are performance indicators, but not all performance indicators are KPI’s. We monitor and measure constantly (or at least we should), but the resulting data may, or may not, be directly relevant to the achievement of our strategic goals. Determining Effectiveness Performance indicators, regardless of whether they’re considered a KPI or not, can only successfully be used to determine the performance and the effectiveness of the QMS if a criterion for effectiveness has been determined. This effectiveness criteria is not necessarily an improvement goal, but rather is used to indicate the extent to which planned activities are realized and planned results are achieved. For example, if a manufacturing process has a rework rate of 2.5%, but an effectiveness criterion of 5%, we can say that the process under consideration is “effective” (2.5% < 5%); it has achieved planned results. In this example, a rework rate of 2.5% is not an improvement goal, but rather it indicates that our expectations have been met, and the process works as intended. Quality Objectives Improvement goals, on the other hard, are realized through the process of establishing, planning and achieving quality objectives. To understand the relationship between performance indicators, KPI’s and Quality Objectives, remember that performance indicators reflect the performance of a process, function, activity, etc., while objectives are tools used to promote improvement of the Quality Management System at a strategic, tactical or operational level. Taking the above example further, if our manufacturing process has a rework rate of 2.5%, but an effectiveness criterion of 5%, we can say that the process under consideration is “effective” (2.5% < 5%); it has achieved planned results. In contrast, a process may have a rework rate of 2.5%, but we want to improve that rate down to 1.65%, we now have the basis for a quality objective. Note also, that the results of the performance indicator (2.5%), the effectiveness criteria (5%), and the quality objective (1.65%) may all exist in the same space, at the same time. Conclusion Simply put, performance indicators do just as the name implies; they indicate the performance of a process or activity, against established effectiveness criteria. Key Performance Indicators (KPI) indicate the performance of a process or activity that is key to the organization’s business strategy. Quality Objectives reflect an improved level of performance desired by the organization.

While the relationship between KPI's and Quality Objectives should be fairly intuitive, most organizations have only so many resources to spread around. We can't improve everything at once, and improvements in some areas provide little or no return. Just like every performance indicator is not a KPI, every KPI does not require a corresponding quality objective. QMS Performance MetricsA Quality Management System (QMS) should be a dynamic system, and provide a framework, for planning, executing, monitoring and improving the performance of quality management activities. In order to take QMS performance to higher levels, we must first understand and track where we are at, in terms of our current level of performance. Performance can be related to the management of activities, processes, products, services, systems or organizations. Performance indicators, therefore, are the metrics we use to track our current performance at functions, levels and processes, in order to make data driven decisions related to the improvement our QMS. Understanding whether our QMS is effective, requires determining and evaluating these performance indicators against established performance criteria. Sample Metrics To aid the reader in understanding the above concepts, I’m including several different metrics as examples. Business is not a one-size-fits-all activity, so the usefulness of these may vary. If any of these metrics are key to your business strategy, they would then be considered Key Performance Indicators (KPI's). Otherwise, they could still be considered, but in such case, they would simply be considered performance indicators. Sample Business Metrics:

Sample Financial Metrics:

Sample Sales Metrics:

Production Metrics

Sample Marketing Metrics:

Sample Project Management Metrics:

Performance Indicators vs KPI'sWhile an organization may likely have many performance indicators, not all metrics are key to its business strategy, and the strategic outcomes determined by the organization.

While it’s common to use performance indicators interchangeably with Key Performance Indicators (KPI’s), such a description is incorrect. It is important to understand that, while all KPI’s are performance indicators, not all performance indicators are KPI’s. To keep these differences clear, just remember the following: “KEY” = key to our business strategy. Congratulations to Watlow (Houston) on their recommendation for ISO 9001:2015 Certification, as applicable to the design/development, manufacturing and delivery of electrical control panels and related services. For more information about their products and services, go to www.watlow.com

Congratulations to Torq/Lite for their recommendation for recertification to ISO 9001: 2015 as applicable to the design and manufacture of torque wrenches and specialty tools and the provision of related training services (Bolting Training School). For more information on their products and services, go to https://www.torqlite.com.

Congratulations to Texas Microelectronics for their recommendation for AS9100 certification and continued ISO 9001 certification as applicable to custom microelectronic circuit design, manufacturing of microelectronic products, and testing services. For more information about their products and services, go to www.texasmicroelectronics.com

|

Our ISO 9001 Blog

Information, thoughts and periodic updates from MAS Solutions. Please Like or Share this page if you find the content useful, so we'll know to keep posting. Enjoy! Archives

April 2020

Categories

All

|

RSS Feed

RSS Feed